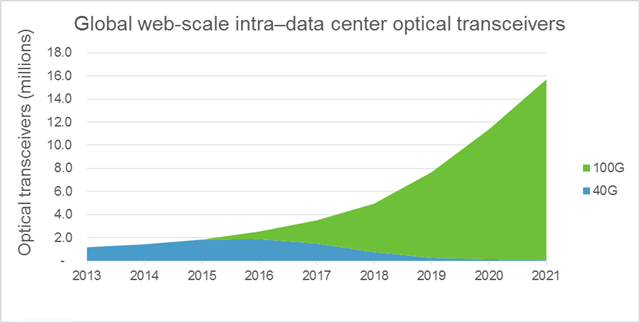

Although 10/40G Ethernet nowadays still captures the major position in the world of telecommunication, service providers and enterprise data centers are actually undertaking a transformation of infrastructures. Which fuels the demand for higher speeds, greater scalability, and better performance and reliability, making migration to 100G network an inevitable trend. Optical transceiver modules always pertain to an integral part of overall system design, as for 100G CFP modules, the options vary widely. This article makes a comparison of the most commonly two: CFP-100G-SR10 and CFP-100G-LR4 transceiver module.

Basics of 100G CFP Transceiver Module

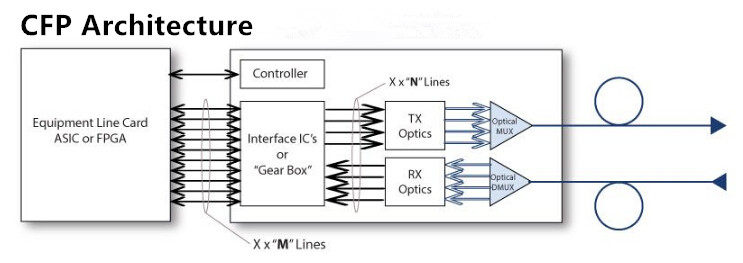

CFP transceiver module is a hot pluggable form factor designed for optical networking applications. CFP the acronym from 100G (here C equals 100 in Roman numerals) form factor pluggable. The name clearly indicates that CFP transceiver module is introduced typically for 100G interfaces. To make it easier to understand, let’s begin with general CFP architecture. It basically consists of two parts—electrical interface interacting with equipment, and line card interface and optical line interface.

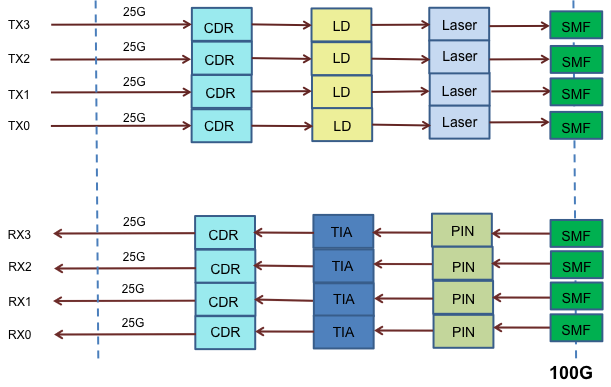

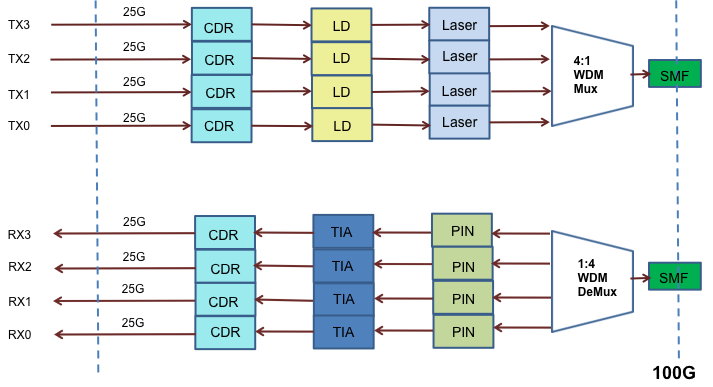

From equipment line card to electrical interface, CFP has several “M-Lines” with 10Gbps speed. If CFP is working 100GBase-LR4 mode, then it has 10 x 10Gbps M-Lines. As for 40GBase-LR4, it uses 4 x 10Gbps M-Lines. The so called “gear box”is electrical 10:4 mux/demux module aggregating up to 10 M-Line interfaces in maximum 4 N-Line interfaces. Each N-Line is 25Gbps for 100GBase-LR4 and 10Gbps for 40GBase-LR4. The N-Line is converted to optical signal with different wavelength and all four wavelengths are transmitted to CFP line interface using built in passive optical multiplexers.

CFP-100G-SR10 and CFP-100G-LR4 Overview

100G CFP modules offer connectivity options for a wide range of service provider transport, data center networking, and enterprise core aggregation applications. The basic information of CFP-100G-SR10 and CFP-100G-LR4 module is provided below.

CFP-100G-SR10 Module

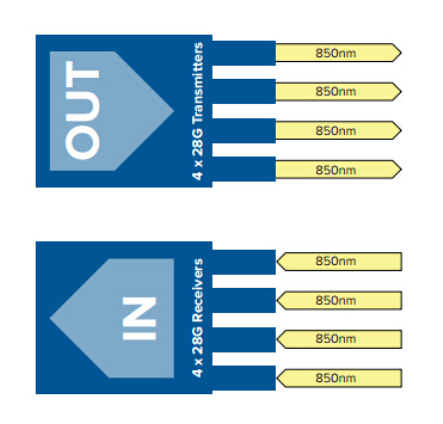

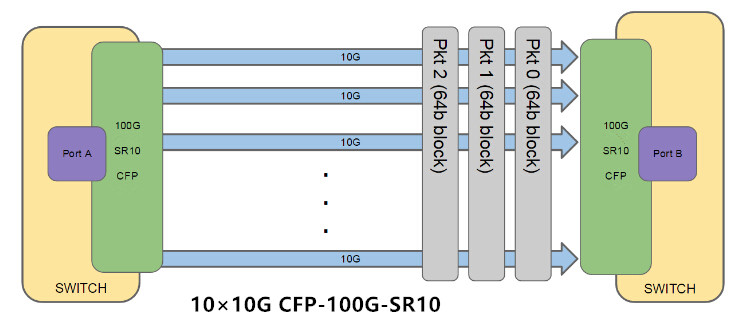

CFP-100G-SR10 is an IEEE standardized CFP module supporting link lengths of 100 m and 150 m respectively on laser-optimized OM3 and OM4 multifiber cables. It primarily enables high-bandwidth 100-gigabit links over 24-fiber ribbon cables terminated with MPO/MTP-24 connectors. It can also be used in 10 x 10 Gigabit Ethernet mode along with ribbon to duplex fiber breakout cables for connectivity to ten 10GBASE-SR optical interfaces. CFP-100G-SR10 interface serves as a more cost-effective solution, which is optimized for data center application and is limited to short distances.

CFP-100G-LR4 Module

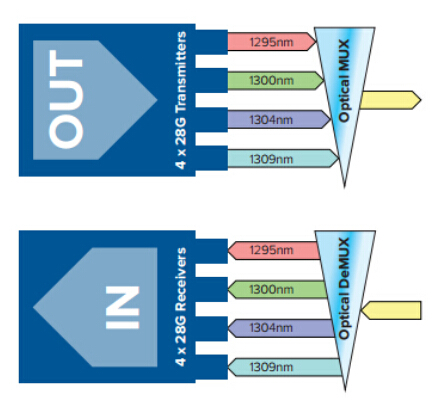

CFP-100G-LR4 is standardized by IEEE using standard LC dual fiber interface with single-mode cable, but running four optical wavelengths each direction (1295.56 nm, 1300.05 nm,1304.59 nm, 1309.14 nm) and muxing/demuxing of these wavelengths happening inside CFP module. Each wavelength is running at 25.78 Gbps and it is possible to achieve up to 10 km. Compared to CFP-100G-SR10, CFP-100G-LR4 delivers much better reach for long-haul applications, but at a cost premium.

Comparison Between CFP-100G-SR10 and CFP-100G-LR4

In this section, we’re trying to figure out the difference between CFP-100G-SR10 and CFP-100G-LR4 from the perspective of connectors and cabling used on each. For connectors, 24-fiber MPO/MTP connector is for CFP-100G-SR10 module while dual SC/PC connector for CFP-100G-LR4. Note that only patch cords with PC or UPC connectors are supported. The cabling specification and features for CFP-100G-SR10 and CFP-100G-LR4 are presented in the following diagrams.

Service providers and data centers are embracing the trend of 100G network migrations, IT managers and network designers must think twice when choosing from those various 100G transceiver options. CFP-100G-SR10 is preferred due to lower cost over LR4, but its reaching distance is limited. Whereas CFP-100G-LR4 enables data transmission up to 10 km with higher price. This article generally offers some basic knowledge of CFP-100G-SR10 and CFP-100G-LR4 transceiver modules, the decision actually depends on your specific demands and requirements of your applications. Always be aware of what you need, which will work best for you.

Source: http://www.fiber-optic-solutions.com/cfp-100g-sr10-cfp-100g-lr4-comparison.html

Source: http://www.fiber-optic-solutions.com/cfp-100g-sr10-cfp-100g-lr4-comparison.html