We know the way that cables are attached to the system is quite essential to the performance of the telecommunication network, be it a wiring closet, a building entrance or at points between the transmitter and the receiver. As the cable is connected properly, it enables optical signals to pass with little return loss and low attenuation. Joining optical fibers with a fiber pigtail is proven and considered to be an effective way to ease fiber termination—which is we are going to talk about in this article.

Fiber Pigtail Overview

Also known as bare fiber, fiber pigtail is a kind of optical cable terminated with an optical connector on one end and unterminated fiber on the other. Therefore the end with a connector can be linked to the equipment while the other side is melted together with another optical fiber. In fact, fiber pigtail can be considered as fiber optic patch cable since they are similar in structure, and a fiber patch cable can be divided into two pigtails. Fiber pigtail has various different interfaces and couplers. Common fiber pigtails are usually with 0.9mm fiber cable diameter, and installed inside ODF unit.

Common Classifications of Fiber Pigtail

Fiber pigtails are available with various kinds based on fiber type, connector type and endface type. Some common classifications of fiber pigtail are listed below.

Classified by Fiber Type

According to fiber type, fiber optic pigtails can be divided into single-mode (colored yellow) and multimode (colored orange) fiber. Multimode fiber optic pigtails use 62.5/125 mm or 50/125 mm bulk multimode fiber cable and terminated with multimode fiber optic connector at one end. Besides, 10G multimode fiber cable (OM3 or OM4) is also available in fiber pigtails. The jacket color of 10G OM3 and OM4 fiber pigtail is usually aqua.

Classified by Connector Type

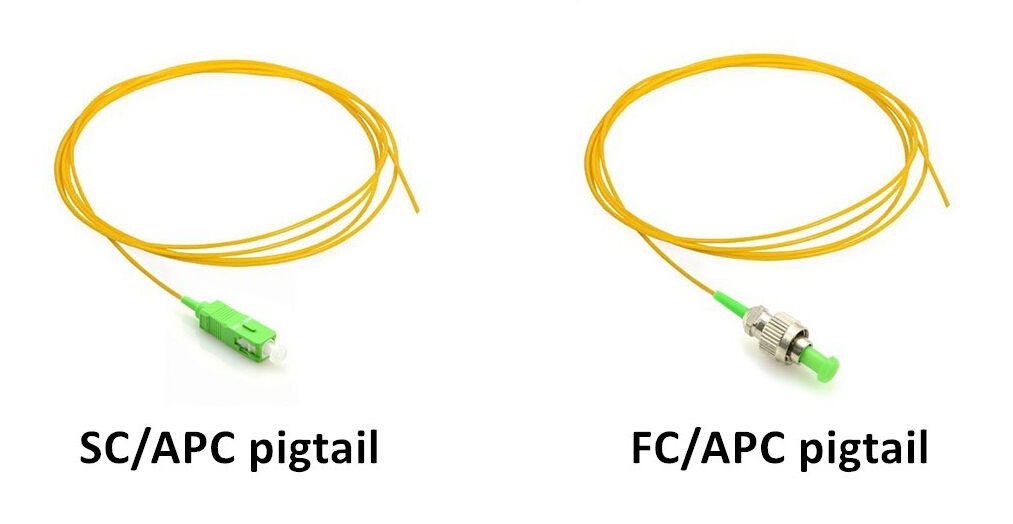

According to different types of fiber connectors that terminated on the end of a fiber pigtail, there are LC fiber pigtail, SC fiber pigtail, ST fiber pigtail, FC fiber pigtail, MT-RJ fiber pigtail, E2000 fiber pigtail and so on. With different structures and appearance, each of them has their own advantages in different applications and systems.

Classified by Endface Type

While based on the endface type, fiber optic pigtails can be divided into UPC and APC versions. Most commonly used types are SC/APC pigtail, FC/APC pigtail and MU/UPC pigtail.

Tips for Easier Fiber Termination With Pigtail

As we have explained at the beginning of the article, fiber pigtail plays a crucial role in ensuring the reliability and performance of the system. Meanwhile, it is a rather critical component to ease fiber termination as well. Let’s see how fiber pigtails achieve this.

Selecting Quality Pigtails

Pigtails are attached to cables by fusion or mechanical splicing, both of which provide a fast termination method and hence speed the termination process. While pigtails bridge a critical junction in the fiber-optic network, installers need to choose one made with reliable components. Basically, pigtails are cable assemblies, which means the parts contained in pigtail—a connector, a ferrule, standard fiber and jacket types, are components that every experienced fiber technician is familiar with.

Among these components, however, the quality of the connector stands out as the most crucial one. And elements like insertion loss, the type of polish used and how well the connector is terminated to the cable are extremely vital. Since you have to use fiber and connector types that meets a particular application’s needs. Selecting the proper product depends on job specifications.

Ferrule material, whether zirconia ceramic, plastic or stainless steel, must also be specified when ordering a pigtail. Notice that always ordering pigtails a few feet more than you think you`ll need. The extra slack allows for splicing errors to be corrected, or you may have to start with another pigtail.

Saving More Labour Cost and Time

While the majority of single-mode applications use pigtails, they are also used in many multimode applications. One of the benefits of the pigtail is lower labor costs: Installers working with single-mode fiber typically have access to a fusion splicer, and with a fusion splicer you just splice the pigtail right onto the cable in a minute or less.

The quality of fiber pigtail is typically high because the connectorized end is attached in a controlled environment--the factory. And the factory can make single-mode pigtails more accurately than a field termination can be done. Testing a pigtail in the field is not easy, because in the field you are dealing with unknowns, but in the factory, you are dealing with credible measurements. Which on the other hand saves much time spent on field termination.

Conclusion

Fiber pigtail serves as a feasible and reliable solution for easier fiber termination, which effectively contribute to save plenty of operating time and labour cost. The performance of fiber pigtail matters a lot, so the quality of connector, ferrule material as well as cable length of pigtails should be considered to ensure easier fiber termination.

No comments:

Post a Comment