The past few years have witnessed a great leap in advancements of fiber optic communication technologies, these progresses are made to cater to the ever accelerating demand for better and more efficient optical performances. Fiber optic splitter, which plays a significant role in optical networks by allowing signals on an optical fiber to be shared among two or more fibers. Basically, there are two types of fiber optic splitters: fused biconical taper splitter (FBT) and planar lightwave circuit splitter (PLC). And each of them obtains some merits and demerits respectively. This article intends to make a comparison of these two thus to provide some useful information about optical splitters.

Introduction to Fiber Optic Splitter

Fiber optic splitter, known as beam splitter as well, is suitable for a fiber optic signal to be decomposed into multi-channel optical signal output. It divides out a main light source into 1-N optical path and synthesizes 1-N optical path into a main light source and recovers this source. The picture below shows how light in a single input fiber can split between four individual fibers.

Basically, there are two types of optical splitters classified by their working principle: one is fused biconical taper splitter (FBT Splitter) made by the traditional optical passive device manufacturers using the traditional biconical taper coupler technology. The other one is planar optical waveguide splitter (PLC Splitter) based on optical integration technology. Since both of them have their own advantages, users can rationally choose different types of optical splitters depending on the occasion and demand. Besides, it is better to follow a brief introduction of these two devices just for reference.

FBT Splitter

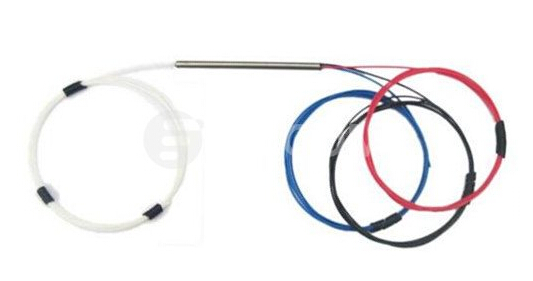

FBT is the traditional technology in which two fibers are placed closely together, typically twisted around each other and fused together by applying heat. The fused fibers are protected by a glass substrate and then protected by a stainless steel tube. The quality of FBT splitters has improved over time and they can be deployed in a cost-effective manner. FBT splitters are widely accepted and used in passive optical networks, especially for where the split configuration is no more than 1x4.

However, when larger split configurations such as 1x16, 1x32 and 1x64 are needed. FBT technology is limited to the number of splits that can be achieved with one coupling. Under such circumstance, multiple FBT splitters can be spliced together in concatenation to multiply the amount of splits available. This is also known as a tree splitter or coupler. When using this design, the package size and the insertion loss increases with the additional splitters and splices used.

PLC Splitter

PLC splitters are used to separate or combine optical signals. A PLC is a micro-optical component based on planar lightwave circuit technology and provides a low cost light distribution solution with small form factor and high reliability. PLC splitters have high quality performance, such as low insertion loss, low PDL, high return loss and excellent uniformity over a wide wavelength range from 1260 nm to 1620 nm and have an operating temperature -40℃ to 85℃. When high split counts are needed and small package size and low insertion loss is critical, a PLC splitter is more ideal.

Differences Between FBT Splitter and PLC Splitter

In this part, we will take a look at the main differences between FBT splitter and PLC splitter from eight perspectives, which are listed in the following diagram.

| Parameters | FBT Splitter | PLC Splitter |

| Fabrication Method | Two or more pieces of optical fibers are bound together and put on a fused-taper fiber device. The fibers are then drawn out according to the output branch and ratio with one fiber being singled out as the input. | Consists of one optical chip and several optical arrays depending on the output ratio. The optical arrays are coupled on both ends of the chip. |

| Operating Wavelength | 1310 nm and ISSO nm (standard), 850 nm (custom) | 1260 nm-1650 nm (full wavelength) |

| Application | HFC (network of fiber and coaxial for CATV), All FTIH applications. | Same |

| Performance | Up to 1:8—reliable. For larger splits reliability can become an issue. | Good for all splits. High level of reliability and stability. |

| Input/Output | One or two inputs with an output maximum of 32 fibers. | One or two inputs with an output maximun of 64 fibers. |

| Package | Steel Tube (used mainly in equipment), ABS Black Module (Conventional) | Same |

| Input/Output Cable | Bare optical fiber, 0.9 mm, 2.0 mm, and 3.0 mm | Same |

| Part Number Example | FOSPLT-T-FBT-1/2-E-SM-SC/APC | FOSPLT-T-PLC-1/2-E-SM-SC/APC |

Conclusion

Although the outer appearance and size of FBT and PLC splitters seem rather similar, their internal technologies and specifications differ in various ways. I hope the comparison made by this article would help you have a better understanding of these two types of optical splitters, so you could choose a more appropriate solution for your network infrastructure.

No comments:

Post a Comment